Factory drive recorder

Manufacturing site DX solutions

Record the moment trouble occurs

What is Factory drive recorder?

Accurately capture various phenomena that occur at the manufacturing site.

It is a solution that accurately captures various phenomena occurring at the manufacturing site as a video by combining various triggers including information from structural equipment and various cameras.

Product Features

- Features1

- Video recorder streamlines identification of the causes of problems

Capturing the unexpected behavior of a robot arm

When a problem such as damage to a product occurs on an unmanned site, it is difficult to determine what happened, and it takes time to identify the cause. By recording the robot's operation status for each production order, it is possible to grasp the situation when the trouble occurred and analyze the cause quickly.

Grasping the state of opening doors of sterile equipment

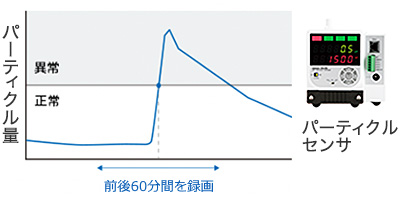

Due to the difficulty of keeping an eye on work sites with sterile equipment, it is difficult to identify the cause of defects, because the condition at the moment of occurrence is not known. For example, an abnormal value for particle count can be used as a trigger to record the machine conditions before and after the defect to help identify the cause.

- Features2

- Record the moment when conditions change

Automatic recording of trouble events with trigger input

Recording the machine status for 60 minutes before and after trouble occurs using Camera External Trigger Input from various sensors and PLCs, or TCP Command Trigger Input to a PC, you can rapidly confirm what happened at the moment of trouble by video playback.

Recording function with production site specifications for a variety of applications

In addition to External Trigger Input, various trigger recording functions are available, such as Time Trigger, Motion Detection, and Master Image Comparison as well as a total of seven types of recording functions, including a maximum recording time of one year for Continuous Recording and 60 minutes for Manual Recording. It can be used for various applications at production sites, such as continuous remote monitoring of machine status, review of production problems, and work process tracing for market trouble (recalls).

- Features3

- 3-step easy system configuration

Step 1. Prepare devices

The camera and dedicated software are bundled together and can be used immediately without programming. There is no need for operational verification or programming, which are required when building a system by combining general cameras with vision software. Recording can be started immediately by using input from the sensor or PLC installed at the production site as a trigger.

Step 2. Install

Install the factory drive recorder software and camera driver (SentechSDK)*1 on your PC or IPC.

Step 3. Set recording conditions

Configure camera settings, recording settings, and settings for saving recorded videos.

Built-in functions

Accurate recording of trouble events with various types of cameras

With an extensive lineup of more than 100 models, you can select the camera that best suits your purpose, such as wide/narrow areas, high-resolution/high-frame-rate, and small cameras for installation in narrow spaces.

Please refer to OMRON SENTECH's website for compatible cameras.

https://sentech.co.jp/en/products/factory/index.html

Click for product inquiries and questions

welcome

- Factory drive recorder corporate customer

-

Contact

Please select "Factory drive recorder"

+81-75-925-0064+81-75-925-0074Business hours: 9:00-17:30

(except Saturdays, Sundays and public holidays)

- private customer

- osk-dx-sales@omron.com

Personnel Division:Information Technology Business Unit Sales Management Department Smart System Sales Group

53 Kunotsubo,Terado-cho, Muko-shi, Kyoto 617-0002, Japan